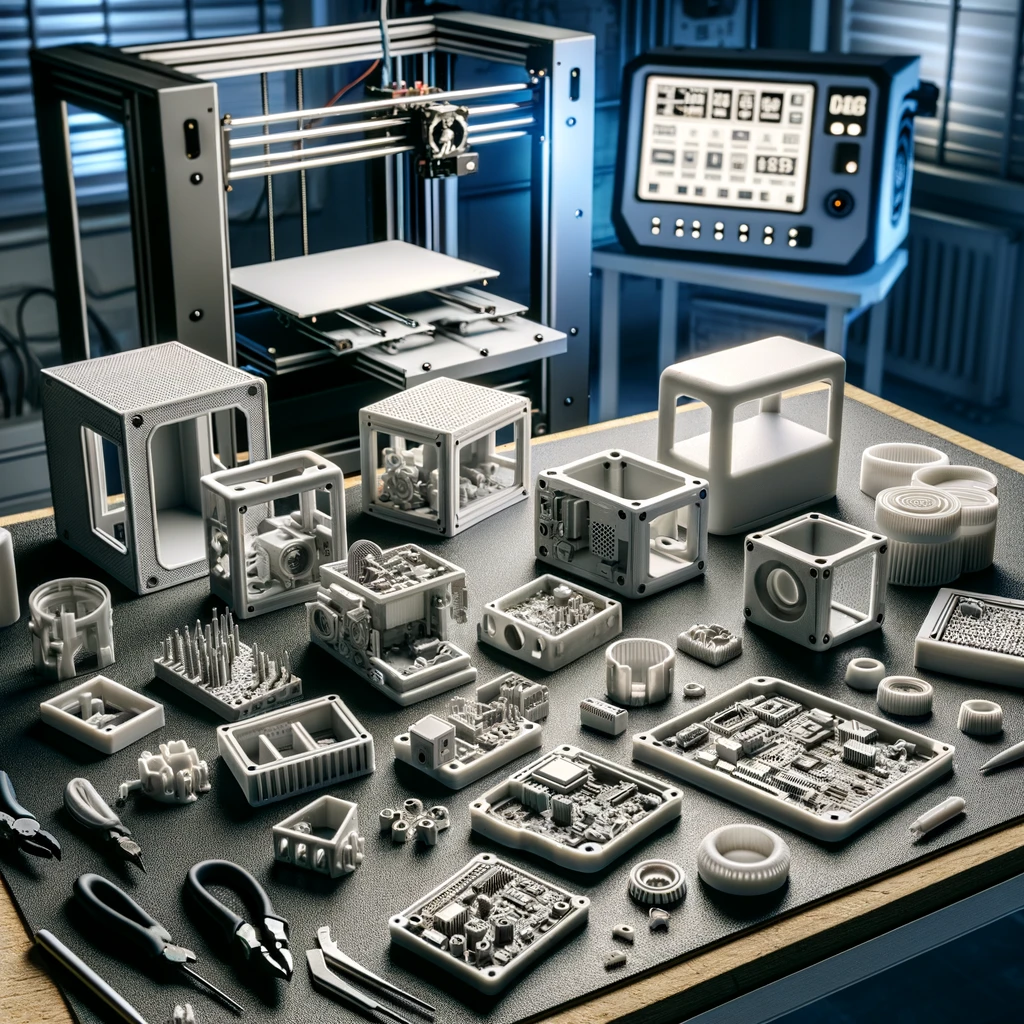

Customized 3D Printed Enclosures for Businesses

In today’s technological world, personalization is a game-changer. Whether you’re an engineer, a product developer, or a manufacturing manager, custom 3D printed enclosures can make the difference between a successful project and a failed one. Reents Technologies offers you a comprehensive solution for tailor-made 3D printed enclosures made to measure.

Why 3D Printing Housings?

The use of 3D printing technology makes it possible to implement complex designs quickly and efficiently. With our 3D printing enclosure service, you can ensure that your electronics enclosures are tailored to your specific requirements. Our service includes the production of 3D printing electronic enclosures, prototyping enclosures and custom 3D printing enclosures.

Benefits of 3D Printed Enclosures

- Precision and customizability: Having custom 3D enclosures printed means that every detail is designed exactly to your specifications. This is especially important for electronics projects where every component needs to fit perfectly.

- Speed: With our 3D printing enclosure manufacturer service, you can realize your designs in no time. This accelerates the development process and reduces time-to-market.

- Cost-effectiveness: Compared to traditional manufacturing methods, 3D-printed packages are more cost-efficient, especially for small quantities or prototypes.

- Design freedom: 3D printing can be used to create complex geometries and delicate structures that would not be possible with traditional methods. This opens up new possibilities for creative and functional designs.

Our service: 3D printed enclosures made to measure

Reents Technologies offers a comprehensive 3D printing service. Whether you want to have a plastic 3D printed enclosure made or need special 3D printed project enclosures – we have the solution for you. Visit our 3D printing service page for more information.

Our service starts with a detailed consultation to understand your specific requirements and wishes. We then use state-of-the-art CAD software to create a precise design of your enclosure. Using our high-quality 3D printing technology, we translate this design into a physical model that meets your highest standards.

CAD Design Service for Perfect Enclosures

A successful 3D printing project starts with a well-thought-out design. Our CAD design service supports you in turning your ideas into concrete plans. We work closely with you to ensure that your 3D printed enclosures meet all requirements. More information can be found on our CAD Design Service page.

Our experienced team of engineers and designers use the latest CAD tools to create detailed and functional designs. These designs are then used in our 3D printing process to produce precise and customized housings.

Materials and technologies

We offer a variety of materials for 3D printing, including various plastics such as PLA, ABS, PETG, and more. Each material has its own properties and benefits that are suitable for different applications. Our team will be happy to advise you on choosing the right material for your specific project.

Our 3D printing technology includes various printing processes, such as FDM (Fused Deposition Modeling), SLA (Stereolithography) and SLS (Selective Laser Sintering). These technologies allow us to meet a wide range of needs, from simple prototypes to highly complex, functional parts.

Applications of 3D Printed Enclosures

3D-printed enclosures are used in many industries, including:

- Electronics: Customized housings for circuit boards, sensors, and other electronic components.

- Medical technology: Individual housings for medical devices and aids.

- Automotive industry: prototypes and functional parts for vehicles.

- Aerospace: Lightweight and robust housings for demanding applications.

- Consumer Goods: Personalized products and enclosures for the end consumer.

Success Stories and Customer Stories

Our customers appreciate the quality and precision of our 3D-printed enclosures. Here are some examples of successful projects:

Holder device in medical technology

A medical research institute needed a special holding device to optimize processes and save time. By using our 3D printing technology, we were able to develop a tailor-made solution that met the exact requirements. This holder device allowed the research team to operate their devices more efficiently and achieve significant time savings.

Development and production of a housing for biometric access system

Another exciting project was the development and production of a housing for a biometric access system. This enclosure had to be not only functional, but also aesthetically pleasing to meet the customer’s high demands. Through our precise CAD designs and high-quality 3D printing, we were able to create an enclosure that met all requirements. Details about this project can be found in our case study.

Spare parts production for one machine

One customer had the problem that the handle of one of his machines was a wearing part that was no longer available on the market. If the handle had been defective, the entire machine would have become unusable. By modeling the handle in detail and then 3D printing, we were able to solve this problem and continue to make the machine usable. You can find out more about this in our spare parts production case study.

Contact us

Do you have an idea for a tailor-made 3D printed housing? Or do you need support in the implementation of your project? Contact us today via our contact page and let’s realize your vision together. Our team is at your side with advice and support and will help you to implement your project successfully.

Conclusion

Individual 3D printed housings are the key to innovative and successful projects. With Reents Technologies, you have a reliable partner at your side who is at your side from the initial idea to the finished product. Take advantage of our 3D printing enclosure service and benefit from our expertise and commitment to quality and precision.

The possibilities of 3D printing are almost unlimited. From the initial concept phase to the finished product, we offer you all services from a single source. Let’s shape the future together and take your projects to the next level. Trust Reents Technologies for your custom 3D printed enclosures and experience the difference precision and innovation can make.