Spare parts production with CAD design and 3D printing (Orbitalum G+F handle)

Reents Technologies GmbH specializes in CAD / 3D design & manufacturing and uses 3D printing technologies to offer tailor-made solutions, such as spare parts manufacturing, for the industry. In a recently completed project, we collaborated with

Kliewe GmbH

, a company active in the field of industrial plant and pipeline construction based in Hamburg. The project involved the development and manufacture of an individual spare part for Orbitalum brand pipe cutting machines that were no longer commercially available.

Challenge: Spare part no longer available on the market

Kliewe was faced with the challenge that the previously used pipe cutting machines from Orbitalum (formerly Georg Fischer G+F) were withdrawn from sale or replaced by a new series of machines and no spare parts were available for them. In particular, the handle with actuation button is affected, which is particularly susceptible to wear and breakage due to its intensive use directly on the customer’s construction site as well as during transport. The alternative of completely replacing several hundred machines would have been associated with considerable costs – especially since the machines currently in use are still fully functional, but can no longer be used without the handle.

Solution: Design and manufacture spare parts in 3D

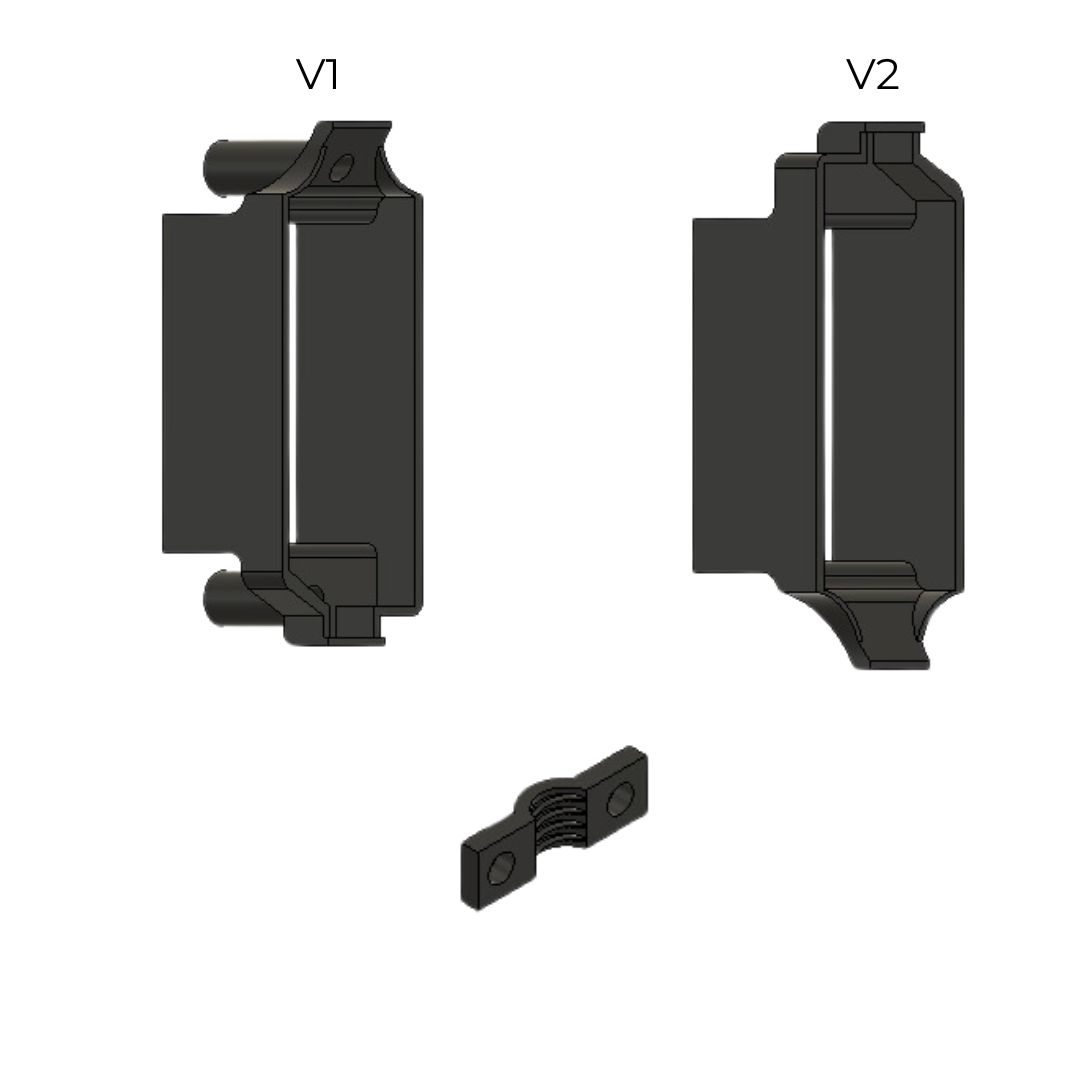

The solution was to develop a 3D model of the spare part in CAD and then manufacture it for Kliewe. The process began with a detailed analysis and measurement of the original handle, followed by the construction of an optimized model using Fusion 360 CAD software. In the first meeting, Reents Technologies visited the customer in Hamburg for an on-site assessment in order to get to know the conditions and the machine and to determine the feasibility. During the development process, emphasis was placed on improving the fit and reinforcing critical areas.

Technical details of the project as well as optimisation of the wear part

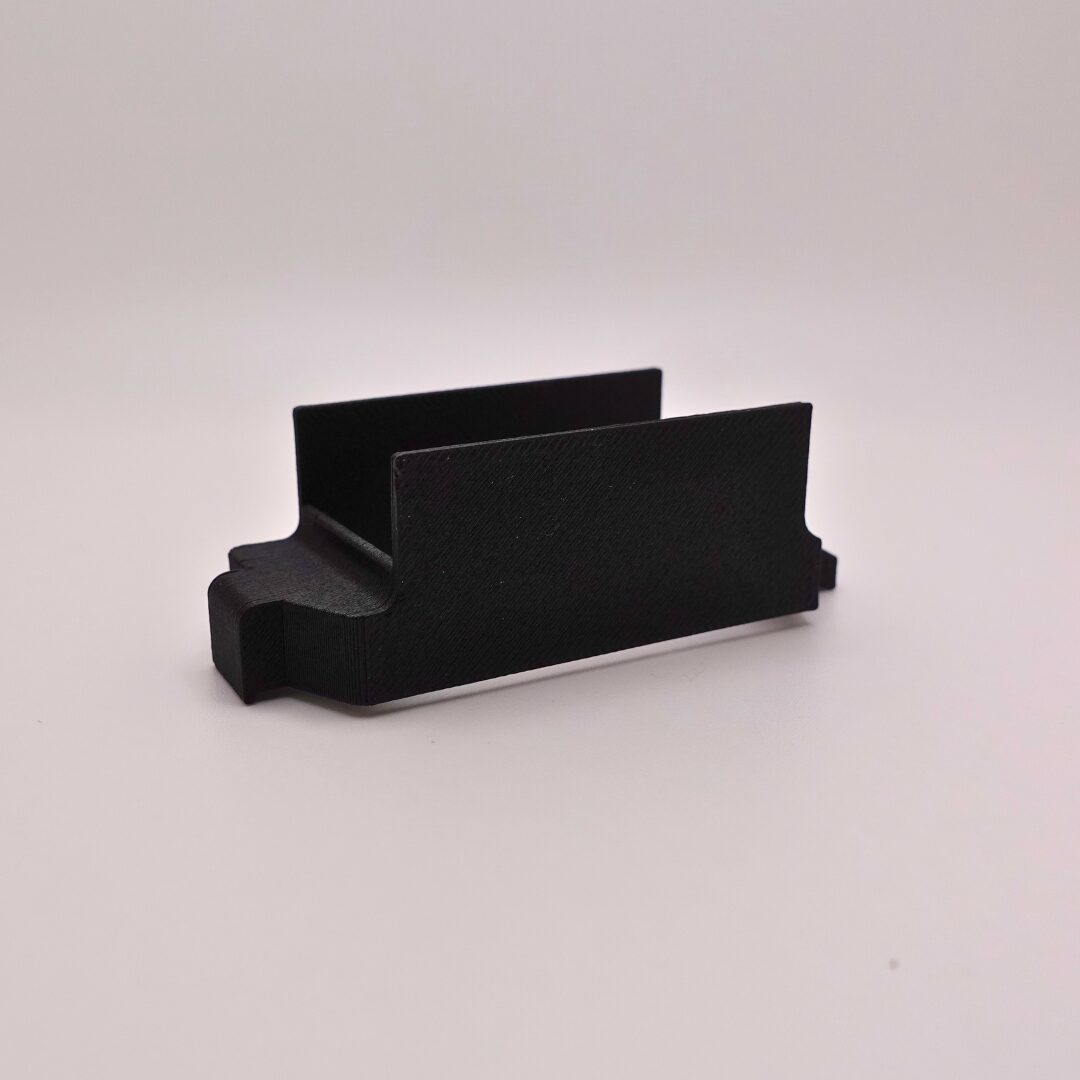

- Material selection: PLA material was used for the prototypes, PETG-CF for the final version to ensure high durability and strength. Production from PACF or ABS material would also be conceivable in the future. In the first series, PETG-CF was finally used. An adaptation of the material can be selected individually for each production.

- Thread adjustments: All threads have been converted to a uniform M4 format to simplify assembly and maintenance. This means that fewer screws have to be stored or purchased in the portfolio for the spare part. Previously, M2.5, M3 and M4 screws were used in the handle.

- Reinforcements: Both the mount on the device and the handle itself have been specifically reinforced to ensure a longer service life under the harsh operating conditions.

Customer feedback: Kliewe expresses its satisfaction

Kliewe GmbH was positive about the solution and the cooperation with Reents Technologies. The ability to respond to specific requirements with tailor-made solutions, as well as the service and fast response time, were particularly appreciated.

Advantages of Spare Parts Manufacturing with 3D Printing Technologies

- Rapid prototyping enables efficient design optimization

- Cost-efficient production of small batches without the need for expensive tooling

- Ability to customize each part to specific requirements

Procedure in this project

- Analysis and measurement of the original handle

- Development of an optimized 3D model

- Production of prototypes to check the fit

- Production of the final spare part in PETG-CF

- Successful implementation and serial production

Further information and contact

For more information about our services in 3D printing service & manufacturing as well as spare parts manufacturing , please visit our website:

Reents Technologies GmbH

Osterbrooksweg 71, 22869 Schenefeld

E-mail: info@reents-technologies.de

Phone: 04056118777

The spare part developed in the project is now also available for purchase here .

Your spare parts project is in good hands with us!

If you are facing similar challenges or are interested in customized spare parts, contact us. We offer individual advice and solutions tailored to your specific needs. Start your project with Reents Technologies and benefit from our expertise in 3D printing technology and manufacturing.