Insight into Additive Manufacturing – Revolution in Modern Production

Insight into Additive Manufacturing – Revolution in Modern Production

Introduction to Additive Manufacturing

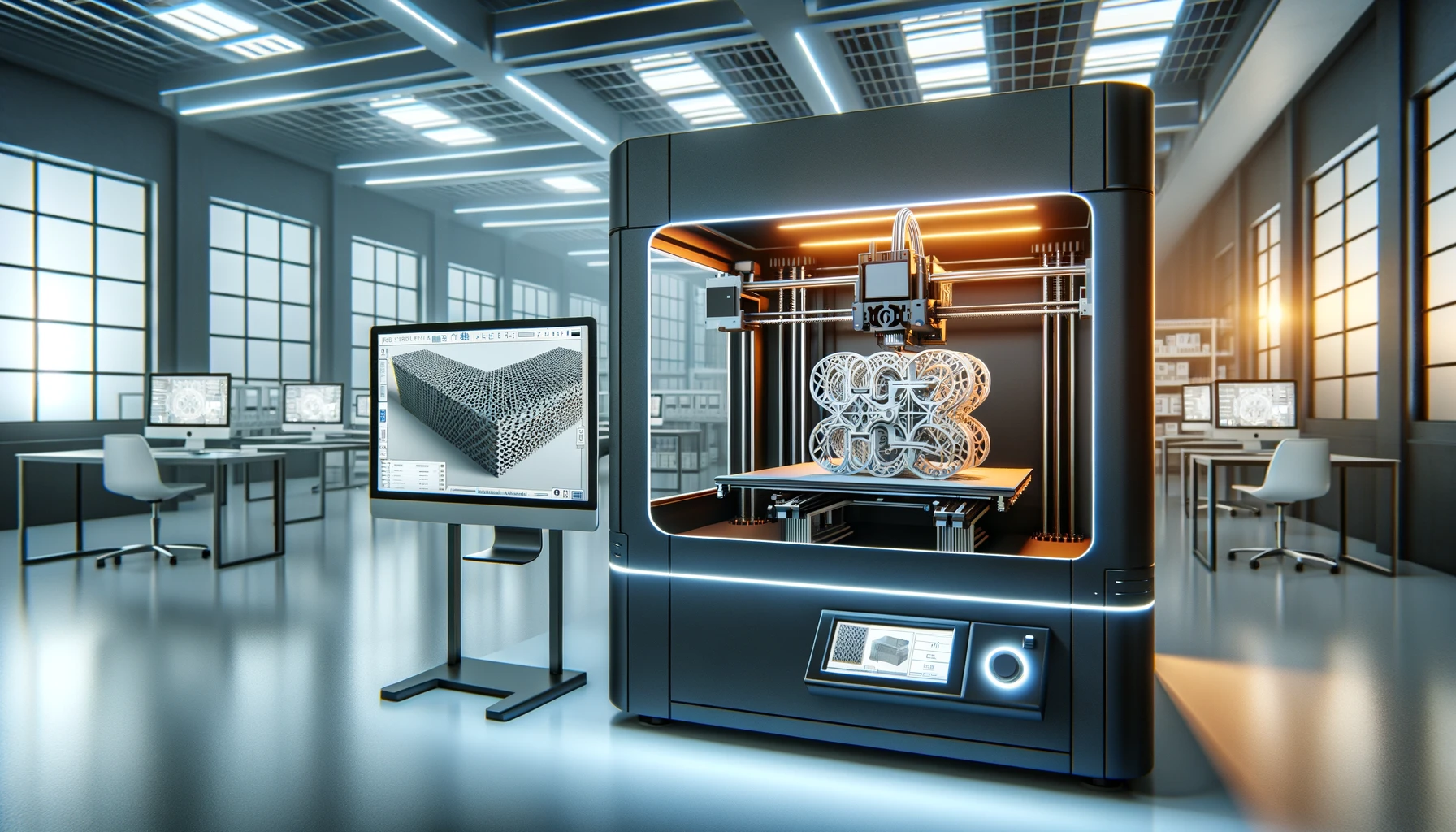

Definition and Overview of Additive Manufacturing: Additive manufacturing, often referred to as 3D printing, is a process in which material is added layer by layer to create complex shapes and structures. This technology has advanced rapidly since its inception in the 1980s and is now a central part of modern industry, known for its efficiency and flexibility.

Brief History of Additive Manufacturing Technology: The origins of additive manufacturing date back to the 1980s, when the first commercial 3D printers were developed. Since then, the technology has continued to evolve, with innovations in various industries and applications.

The importance of additive manufacturing in today’s industry: Today, additive manufacturing is an integral part of Industry 4.0, enabling rapid prototyping, complex designs, and helping to reduce material waste.

Fundamental Technologies of Additive Manufacturing

- Stereolithography (SLA): This technique uses ultraviolet light to turn liquid plastics into solid objects. It is known for its precision and is often used for fine details.

- Selective Laser Sintering (SLS): SLS uses lasers to melt powdery materials such as metal, ceramics or plastics and bond them into solid structures.

- Fused Deposition Modeling (FDM): Here, a thermoplastic filament is heated and extruded into layers to form an object. This method is widely used and inexpensive.

Comparison and areas of application of the technologies: Each of these technologies has its specific strengths and areas of application. SLA is particularly suitable for precise and detailed models, SLS is ideal for robust and functional parts, and FDM is often used for fast and cost-effective prototypes.

Benefits of Additive Manufacturing

- Reduction of material waste through precise use of materials.

- Accelerate product development through rapid prototyping.

- Complexity and design freedom that traditional manufacturing methods can’t provide.

- Case studies that demonstrate the difference in different industries.

Areas of application of additive manufacturing

Use in the aerospace industry: From the production of lightweight but robust parts to complex components.

Significance for the automotive industry: Rapid prototyping, production of final parts and tools.

Innovations in the medical sector: Personalized medical devices, prostheses and implants.

Personalized Products and Retail: Tailor-made consumer goods tailored to the individual needs of customers.

Challenges and outlook for the future

Current challenges include material costs, print speed, and scalability. Future developments could include faster printing methods, improved materials, and more advanced design software. The role of additive manufacturing in sustainable production is becoming increasingly important as it helps reduce waste and energy consumption.

Conclusion

Additive manufacturing has established itself as a revolutionary technology in modern production. Companies such as Reents Technologies GmbH use this technology to develop innovative products and bring them to market. Looking ahead, Reents Technologies GmbH is expected to continue to be at the forefront of this development and drive new, exciting projects in additive manufacturing.