FDM vs. SLA: Which 3D printing process fits your project vision?

The world of 3D printing offers a wealth of opportunities for designers, engineers, and hobbyists to turn their ideas into reality quickly and efficiently. In this dynamic field, two technologies in particular are in the spotlight: Fused Deposition Modeling (FDM) and Stereolithography (SLA). Each technology has its unique strengths and weaknesses that make it suitable for different types of projects. In this article, we will thoroughly analyze and compare both technologies to help you make the best choice for your project vision .

FDM Technology

Fundamentals of FDM Technology FDM, or Fused Deposition Modeling, is a 3D printing process that involves applying material layer by layer. A plastic filament is passed through a heated nozzle and precisely deposited on the construction surface or on top of the previous layer.

Pros and Cons of FDM FDM printers are usually inexpensive to purchase and operate. They offer a wide range of materials and are ideal for printing large, long-lasting parts. However, they are limited in terms of resolution and surface quality.

Ideal applications for FDM FDM is ideal for prototyping, functional model manufacturing, and final products where high strength and thermal stability are required.

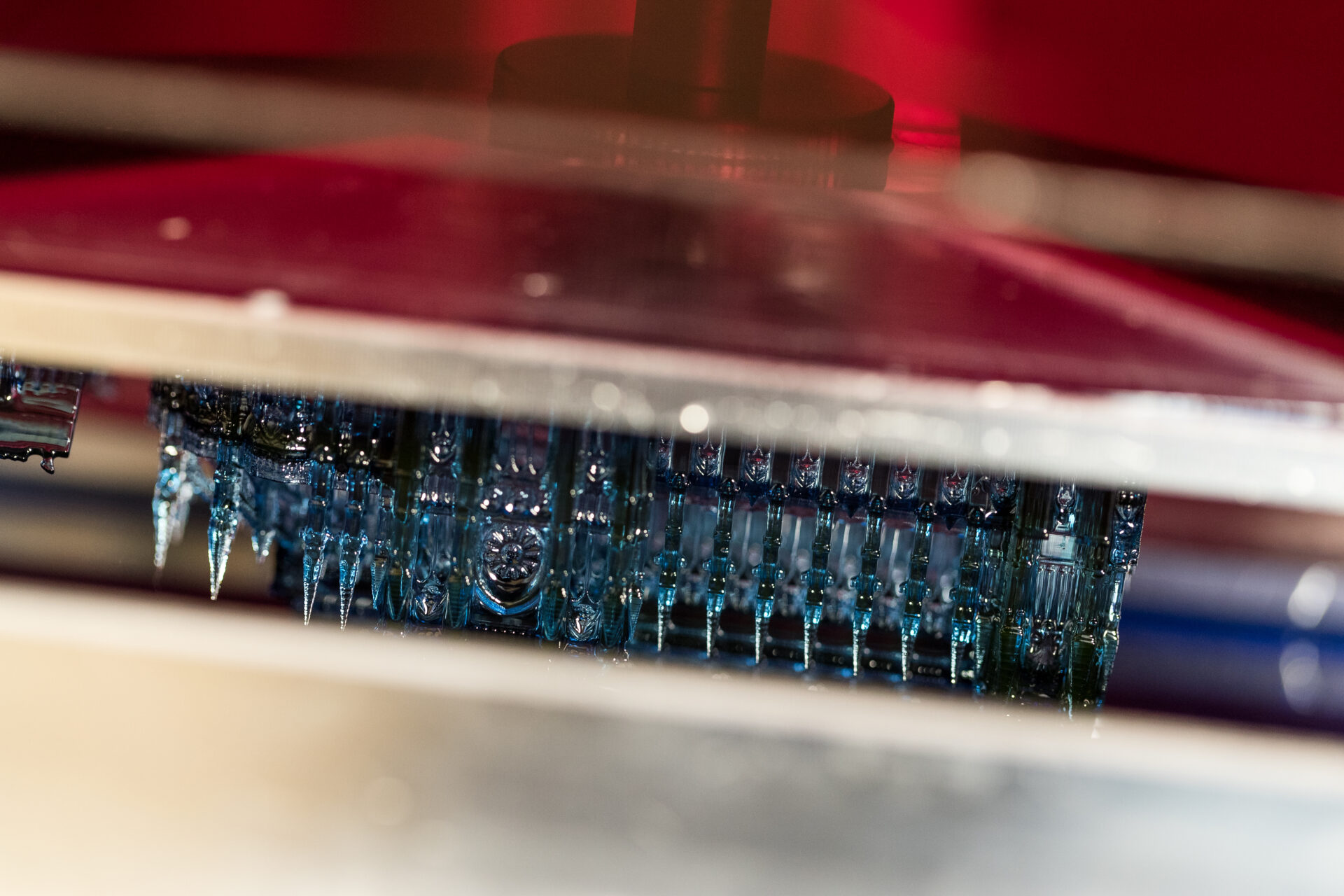

SLA Technology

Fundamentals of SLA Technology Stereolithography (SLA) is a 3D printing process that uses a laser to cure photoreactive resins. This technology is known for its precision and ability to create complex details and smooth surfaces.

Pros and Cons of SLA SLA offers high resolution and surface quality. It’s ideal for applications where attention to detail is critical. However, the cost of materials is usually higher, and the printed parts can be less robust than those of FDM printers.

Ideal applications for SLA SLA is often used for prototypes, models, and products that require fine details or a smooth surface, such as jewelry, dental products, or medical models.

Comparison: FDM vs. SLA

Print quality and resolution

While FDM is known for fast and cost-effective prototyping, SLA offers superior detail and surface finish. However, this quality comes at a price and requires more careful post-processing.

Variety of materials and durability

FDM offers a wide range of material options, including specialized filaments for increased strength or flexibility. While SLA resins offer a fantastic level of detail, they are often less resistant to environmental factors and stresses.

Speed and cost

FDM printers tend to be faster and less expensive to operate than SLA printers. The cost of SLA materials and the need for careful post-processing can increase the overall cost.

Practical application examples

Case studies show how FDM and SLA are being successfully used in various industries to create innovative solutions that traditional manufacturing methods cannot achieve.

Decision

Before choosing a technology, you should consider the following questions: What level of detail is required? How important are the cost of materials? How robust does the end product need to be?

Summary and Recommendation

The choice between FDM and SLA depends heavily on the specific needs of your project. Carefully consider the pros and cons of each technology to make the best decision.

The waterproofness depends on the material used and the printing technique. Some 3D printed parts can be waterproof or made waterproof through post-processing, but it’s important to specify this before manufacturing.

Yes, 3D printing is particularly suitable for the production of one-off pieces or small series without incurring high costs.

The security of your intellectual property is a top priority at Reents Technologies. All our employees are not only bound by confidentiality, but also contractually bound to treat your data and projects confidentially.

In addition, we offer the option of keeping your printed object under lock and key even after production. This ensures that your project remains protected even from the eyes of potential visitors to our manufacturing and production facilities. Your designs and prints will be kept safe and confidential at all times.

We understand the importance of protecting your innovative ideas and are committed to ensuring the confidentiality and security of your intellectual property.

Yes, our team provides comprehensive support, including design advice, to ensure your 3D model is optimally prepared for printing. We’ll help you evaluate feasibility and optimize the design for printing.

The durability of 3D printed parts depends on the material used and the intended use. At Reents Technologies, we use high-quality materials and advanced printing techniques to ensure your parts meet the requirements.

Yes, in addition to printing, we also offer professional post-processing to further improve the quality and appearance of your 3D printed parts. This includes, among other things, grinding, painting or dyeing the parts.

To do so, please contact us individually.

Yes, at Reents Technologies you can upload your own 3D file in STL or STEP format via our Instant 3D Printing Quote Calculator . Our calculator calculates the required material as well as the printing time and gives you an offer, which you can also buy immediately through our shop. We then produce and ship your print directly.

If there is something wrong with your print file or if production according to our quality standards is not possible, we will contact you directly.

The accuracy of 3D printing depends on the printing technology and machine settings. FDM and SLA printing processes from Reents Technologies provide high precision suitable for most applications. We will be happy to advise you on the specifications of our printers and the possibilities they offer for your project.

FDM 3D printing approx. 1/10 mm

SLA 3D printing approx. 1/20 – 1/50 mm

Yes, 3D printing can also be used to produce moving parts or complex assemblies in a single printing process. This technology makes it possible to create designs that would not be possible with traditional manufacturing methods.

The printing time depends on the size of the object, the complexity of the design and the printing technology chosen. At Reents Technologies, we use efficient printing processes and can give you an estimated completion time after reviewing your project.