Additive manufacturing against bottlenecks and supply gaps

In modern industry, efficiency and speed are crucial. Bottlenecks and supply gaps can bring the entire production process to a standstill and cost companies dearly. This is where additive manufacturing, also known as 3D printing, comes into play, offering a revolutionary solution to these challenges. As a leader in the field of additive manufacturing, Reents Technologies GmbH from Schenefeld near Hamburg is ready to help you overcome these challenges.

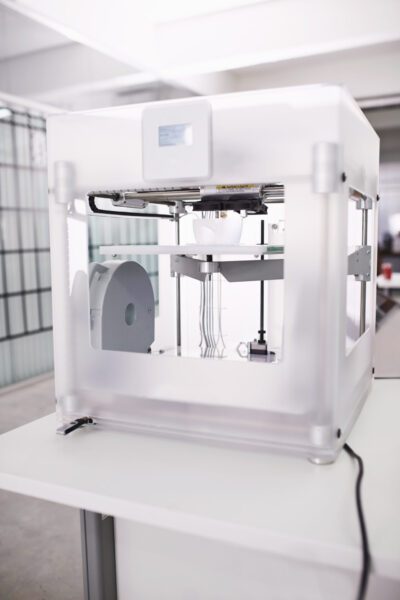

What is additive manufacturing?

Additive manufacturing is an innovative process in which three-dimensional objects are created layer by layer from digital models. This technology enables the fast and cost-efficient production of components and prototypes that would be difficult or impossible to realize with traditional manufacturing methods.

Advantages of additive manufacturing

1. Flexibility and adaptability

Additive manufacturing offers exceptional flexibility as it makes it possible to create complex geometries and customized designs. Companies can respond quickly to specific customer requirements and offer customized solutions.

2. Reduced lead times

Traditional manufacturing methods often require long lead times to produce tooling and molds. With additive manufacturing, companies can dramatically reduce these times by moving directly from the digital model to the finished product.

3. Cost-effectiveness

Additive manufacturing reduces the need for expensive tools and molds, which enables significant cost savings, especially for small batches and prototype production. It also minimizes material waste, as only the amount of material actually needed is used.

4. Rapid prototyping

Companies can create and test prototypes in a very short time, accelerating the innovation cycle. At Reents Technologies GmbH, we offer a rapid prototyping service that allows you to turn your ideas into reality within 48 hours. You can find out more about this on our services page.

Additive manufacturing as a solution to bottlenecks

Supply chain bottlenecks can arise for a variety of reasons, whether it’s unforeseen demand, delivery delays, or production downtime. Additive manufacturing offers decisive advantages here:

- On-Demand Production: Companies can produce parts and components on demand instead of holding large inventories. This reduces storage costs and increases flexibility.

- Local production: Additive manufacturing allows companies to position production units closer to the end customer, reducing delivery times and costs.

- Quick Customization: In the event of changes in demand or product changes, companies can react quickly and produce new parts without the need for long changeover times or new tooling.

Practical example: Reents Technologies GmbH

As a pioneer in additive manufacturing, Reents Technologies GmbH offers comprehensive services to optimize your production processes and overcome bottlenecks. Our expertise in CAD design and 3D printing allows us to provide you with tailor-made solutions tailored to your exact needs.

- CAD Design Service: Our CAD design service helps you turn your ideas into digital models. Learn more about our CAD design service.

- Prototype production: With our rapid prototyping, you can quickly test and adapt your designs, reducing development times and speeding time to market.

Material Diversity in Additive Manufacturing

Another advantage of additive manufacturing is the wide range of materials available, which make it possible to create products for different applications and requirements. At Reents Technologies GmbH, we work with a wide variety of materials, including:

- ABS (Acrylonitrile Butadiene Styrene): A cost-effective material with high impact resistance and heat resistance, ideal for long-lasting products.

- PLA (Polyactide): A bio-based material that is easy to print and is great for prototypes and models.

- TPU/TPE (Thermoplastic Elastomer/Polyurethane): Flexible material, ideal for products that require high fatigue strength and flexibility.

- PETG (polyethylene terephthalate with glycol): Chemically resistant and water-resistant, ideal for waterproof enclosures and containers.

- Composite materials such as PETG-CF, PA6-CF, PA10-CF and PA12-CF

- Compliance with UL standards or other specifications

The Future of Additive Manufacturing

The future of additive manufacturing is promising. New materials and advanced printing technologies are continuously expanding the range of applications. Companies that adopt this technology early on can achieve significant competitive advantages.

Conclusion

Additive manufacturing is a transformative technology that helps companies overcome bottlenecks and supply gaps. At Reents Technologies GmbH, we are committed to providing you with the best solutions and services to optimize your production processes and increase your competitiveness.

Visit our contact page to learn more about our services and how we can help you achieve your production goals.

Integrating additive manufacturing into your production processes not only offers the opportunity to overcome current challenges, but also to unlock future innovation opportunities. Rely on Reents Technologies GmbH as your reliable partner in additive manufacturing and secure your position at the forefront of the industrial revolution.