1 Inch Ball Bracket for Item Profiles (Profile 8) for Industrial Project

Project Details

By:

Riko ReentsIn cooperation with a customer from the industry, Reents Technologies GmbH has developed a tailor-made 1-inch ball head bracket that can be integrated into the proven item profiles . This innovative solution makes it possible to flexibly and securely attach various objects to machine profiles, including movable displays, trays and smartphones. The project goal was to create a multifunctional bracket that fits seamlessly into existing system architectures and opens up new possibilities for use.

Aim of the project

The primary goal was to develop a mounting option for a 1-inch ball head that could be mounted on an item profile. The customer needed a solution to attach a movable display to a machine design. The mount should be robust enough to ensure stability even under heavy loads, and at the same time flexible to enable a wide range of applications.

Technical implementation

Additive manufacturing

-

- Additive Manufacturing (FDM)

- Materials: PA12, PETG-CF

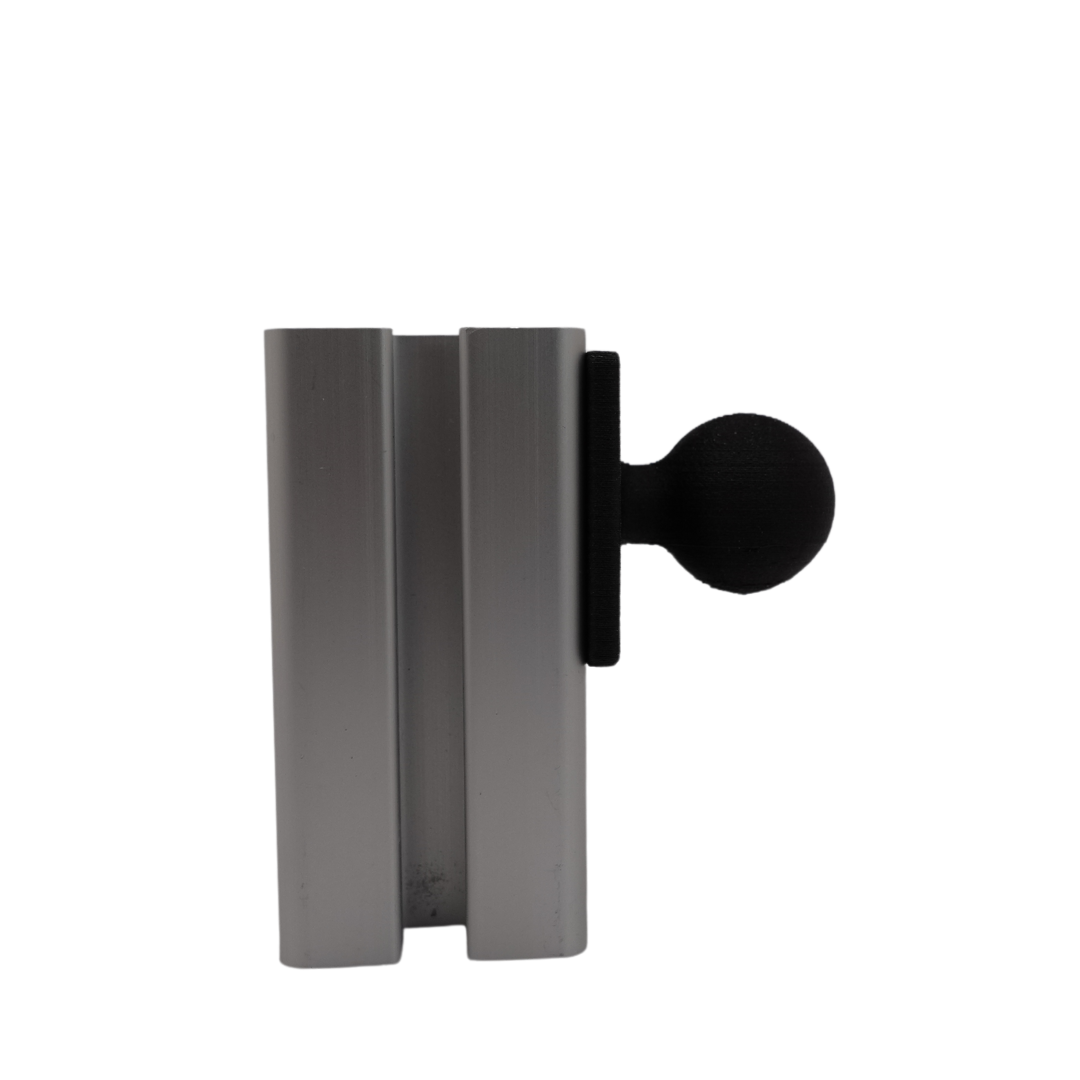

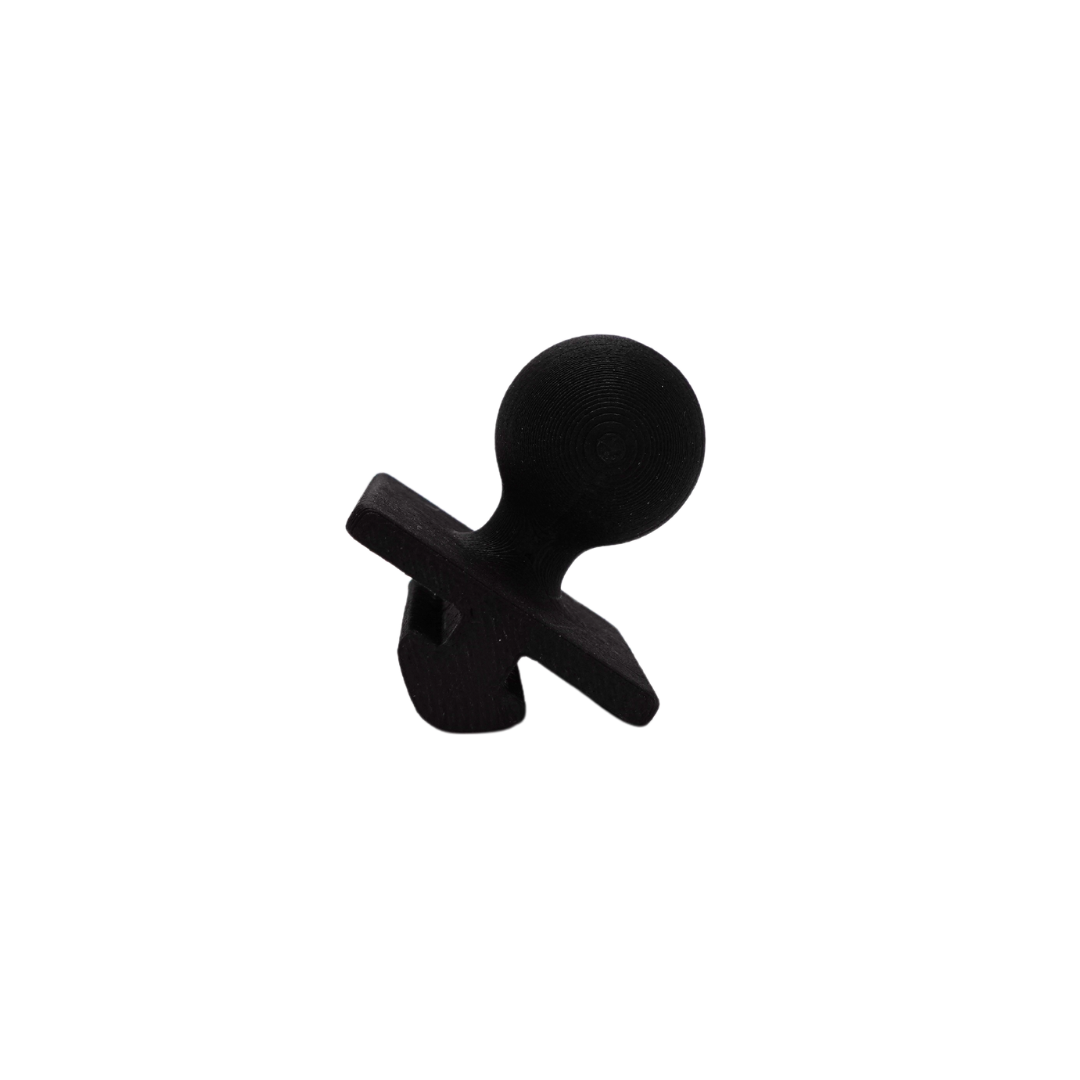

- Rubber: In order to ensure greater adhesion and stability of the attached object, the ball head was finally covered with a special rubber coating. This prevents slipping or twisting, even with heavier weights.

CAD Design

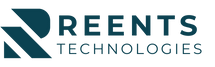

- Item Profile: First, the item profile was precisely modeled in the CAD system to ensure a precise integration of the bracket. Item’s Series 8 profiles offer the widest range of variants and are ideal for industrial applications.

- Ball head mount: The 1-inch ball head mount was then modeled, which allows for a smooth connection between the ball and the item profile.

Design and functionality

- Integration into Item Profiles: The mount has been designed to be seamlessly recessed into the 8 Series item profiles. These profiles are known for their robustness and flexibility, with a tensile load of up to 5,000 N and the use of M8 bolts.

- Versatility: The 1-inch ball head provides a universal mounting platform that is compatible with a wide range of counterparts. These include mounts for displays, trays, smartphones and many other applications. The bracket thus closes a significant gap in fastening technology and significantly expands the possible applications of machine profiles.

Design features

- Rubber-coated ball head: The rubber coating of the ball head ensures increased adhesion and prevents the attached objects from slipping, even under high loads. This is especially important in industrial environments where safety and stability are critical.

- Mounting hole: Inside the 1-inch ball, a hole has been provided for a possible screw connection. This additional screw connection option increases stability and enables the ball head to be securely mounted on the profile.

- Multifunctional use: Compatibility with various mounting systems makes the solution extremely versatile and can be used in a wide range of industrial applications.

Application at the customer

The customer uses the developed bracket to attach a movable display to an item profile of his machine. This solution offers several advantages:

- Increased flexibility: The display can be easily moved to different positions, which improves the operability and ergonomics of the machine.

- Robustness: The high load capacity of the mount ensures that the display remains stable even in harsh operating conditions.

- Aesthetics: The seamless integration into the existing machine design contributes to a professional and appealing appearance.

Development process

The development process began with an intensive analysis of the customer’s requirements and the specific operating conditions. After CAD modelling and initial drafts, prototypes were created and subjected to various tests to verify resilience and functionality. This iterative development made it possible to continuously optimize the design and adapt it to the customer’s needs.

Series production in additive manufacturing

After a successful prototype phase and approval by the customer, the bracket was transferred to series production. Reents Technologies GmbH ensures that every unit manufactured meets the highest quality standards and meets the individual requirements of the customer.

Success story

The 1 inch ball head mount has proven to be a multifunctional and robust solution that can be used in various industrial applications. The customer was extremely satisfied with the flexibility and stability of the solution, which not only meets practical requirements, but also significantly expands the functionality of the machines.

Conclusion

This project impressively demonstrates the capabilities of Reents Technologies GmbH in the field of additive manufacturing and CAD design. By using state-of-the-art technologies and working closely with our customers, we are able to develop tailor-made solutions that meet the requirements of the industry. Our manufacturing expertise and ability to respond quickly to new challenges allows us to deliver innovative products that are both functional and aesthetically pleasing.

If you are interested in our services or would like to realize a similar project, we are always at your disposal. Together, we are shaping the future of industrial manufacturing.